Enhance Your Projects With Specialized Welding Services: Kinds and Advantages

On the planet of building and manufacturing, the significance of specialized welding services can not be overstated. From detailed tasks that demand precision to large-scale industrial applications, the best welding method can make a considerable difference in the result of a job. As advancements in modern technology proceed to shape the welding sector, understanding the kinds of specialized welding solutions readily available and the advantages they provide is crucial for remaining ahead in an open market. Whether it's the influence on construction tasks, the applications in the manufacturing industry, or the advantages for various industries, discovering the realm of specialized welding solutions reveals a world of opportunities that can boost tasks to new elevations.

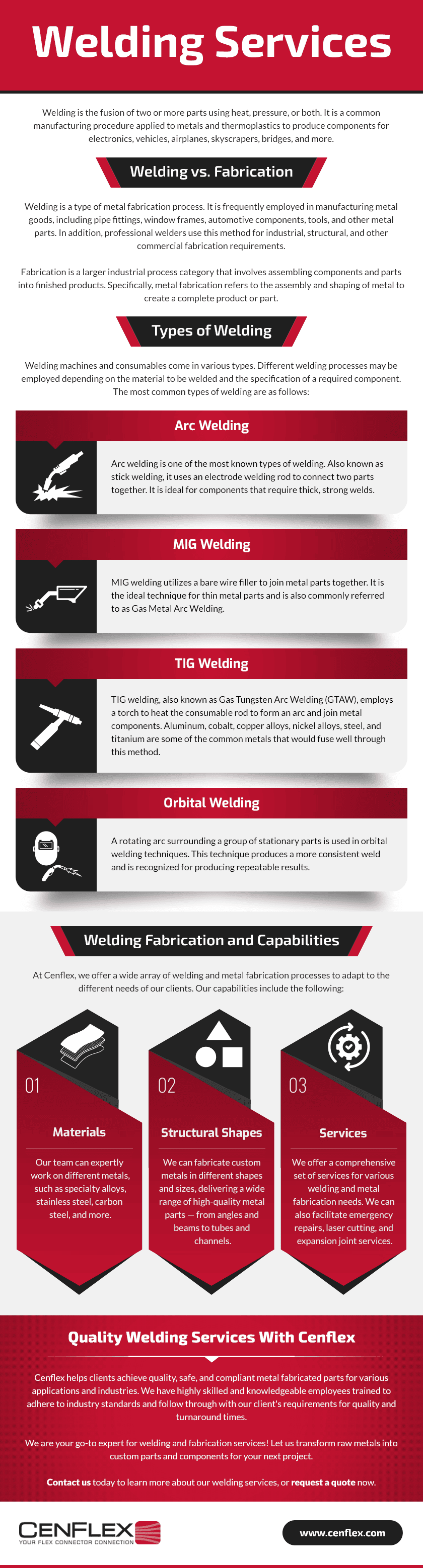

Kinds Of Specialized Welding Solutions

Specialized welding services incorporate a variety of techniques customized to details industrial applications, consisting of yet not restricted to TIG welding, MIG welding, and immersed arc welding. Tungsten Inert Gas (TIG) welding, known for its accuracy and clean welds, is generally utilized in markets calling for high-grade welds on materials like stainless steel and light weight aluminum.

Each of these specialized welding methods offers one-of-a-kind benefits customized to certain job needs, highlighting the value of selecting the proper technique based on product, density, and desired weld attributes.

Benefits of Specialized Welding Solutions

The benefits of using specialized welding services in industrial applications are manifold, varying from boosted precision to increased efficiency in managing certain materials and job demands. One significant benefit of specialized welding services is the competence and experience that welders give the table. These specialists are trained in different specialized welding methods, making sure that the welding procedure is accomplished with the highest possible level of ability and precision.

Effect On Building Jobs

Making use of the knowledge of specialized welding solutions in industrial applications, the influence on building and construction projects is substantial in terms of accuracy, performance, and total quality of welds. Building and construction jobs rely greatly on the structural integrity of bonded elements, making the precision supplied by specialized welding vital. By using specialized welding solutions, building groups can make certain that each weld satisfies the needed specifications, lowering the risk of architectural failures.

Additionally, specialized welding techniques boost efficiency in building and construction projects by enhancing the welding process. With specialized devices and qualified professionals, tasks that would certainly otherwise be time-consuming can be finished faster without jeopardizing top click this site quality. This effectiveness not just accelerates project timelines however likewise minimizes labor costs associated with welding.

Furthermore, the general high quality of welds in building jobs is substantially boosted through specialized welding solutions. These solutions usually involve advanced welding innovations and extremely proficient welders that can produce more powerful, extra durable welds. The exceptional high quality of welds attained via specialized solutions contributes to the longevity and reliability of construction projects, guaranteeing that structures stay audio and risk-free for several years to come.

Applications in Manufacturing Industry

Within the manufacturing sector, the utilization of specialized welding services plays an essential role in guaranteeing the stability and effectiveness of production processes. Welding is a basic procedure in production, made use of in numerous applications such as signing up with steel elements, fabricating frameworks, and repairing equipment. Specialized welding strategies like TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and robotic welding are thoroughly utilized to satisfy the industry's specific demands.

One considerable application of specialized welding in manufacturing remains in the automotive market. Welding is essential in the assembly of vehicle elements, guaranteeing structural security and safety. In addition, the aerospace market greatly relies upon specialized welding services to make airplane elements with high accuracy and stamina to endure extreme conditions.

Furthermore, in the manufacturing of machinery and tools, specialized welding plays an important function in creating durable and reputable items. By utilizing sophisticated welding approaches, manufacturers can improve item quality, enhance manufacturing performance, and ultimately deliver exceptional items to the market - Welding Inspection Service. The intricate and exact nature of specialized welding services makes them essential in the production market's mission for innovation and excellence

Advantages for Numerous Industries

With the critical function that specialized welding solutions play in the production market, it is noticeable that their benefits expand across different fields, providing essential benefits for different markets. One substantial benefit is raised efficiency. Specialized welding techniques enable faster production processes, minimizing downtime and raising overall performance in sectors such as automotive manufacturing, aerospace, and construction. Specialized welding solutions supply boosted accuracy and high quality control, making sure that the final item fulfills stringent sector requirements. This precision is especially essential in industries such as electronic devices making and clinical devices production, where also small flaws can have significant effects. Furthermore, specialized welding solutions can assist markets meet certain regulative needs, such as those in the oil and gas sector or the nuclear sector, where security and reliability are critical. By leveraging specialized welding solutions, different industries can improve their procedures, boost product quality, and inevitably accomplish greater success in today's affordable market.

Final Thought

To conclude, specialized welding solutions offer a variety of benefits for building projects and the manufacturing market. With numerous kinds of welding solutions readily available, such as robot welding and laser welding, organizations can boost the top quality and efficiency of their projects. The impact of specialized welding services prolongs throughout numerous markets, supplying benefits in regards to precision, cost-effectiveness, and toughness. Welcoming specialized welding solutions can result in enhanced project Discover More end results and my site raised competitiveness out there.

As developments in technology proceed to form the welding market, comprehending the types of specialized welding solutions offered and the benefits they supply is important for staying ahead in an affordable market.Specialized welding services encompass a range of strategies tailored to specific commercial applications, including yet not limited to TIG welding, MIG welding, and submerged arc welding.Moreover, specialized welding services usually use advanced tools and innovations that are specifically created for complex welding tasks. Specialized welding techniques like TIG (Tungsten Inert Gas) welding, MIG (Steel Inert Gas) welding, and robotic welding are thoroughly employed to fulfill the industry's certain requirements.

Comments on “Precise Welding Inspection Service for Metal Fabrication”